NASA Awards Four SBIR Awards For ISAM

NASA has announced the winners of their Phase I Small Business Innovation Research (SBIR) investment grants to small businesses, which include four companies who submitted proposals under the category “Servicing and Assembly Applications,” or ISAM.

Per the Phase I application, the topic category was:

Technology development efforts are required to enable in-space servicing for commercial satellites and robotic and human exploration. In-space servicing, assembly, and manufacturing (ISAM) is an emerging national initiative to transform the way we design, build, and operate in space. The goal of the initiative is to develop a strategic framework to enable robotic servicing, repair, assembly, manufacturing, and inspection of space assets. This subtopic addresses key servicing gaps / shortfalls in the Space Technology Mission Directorate (STMD) roadmap.

The winners are:

Creare LLC*

Proposal Title: Compressor for In-Space Gas Transfer and Pressurization

Principal Investigator: Michael Izenson

Estimated Technology Readiness Level (TRL Begin – TRL End): 3 – 4

Summary Details: Future space exploration missions will entail extended, complex operations in space or on lunar and planetary surfaces, including many that require the efficient transfer and compression of gaseous propellant, pressurant, expendables, or products.

Storage pressures may be extremely high, and gases of interest range from helium toxen on. Creare proposes to develop an innovative, compact compressor that will enable collection of essentially all the gas from the supply vessel while pressurizing to extremely high pressures (up to 6,000 psia) in the receiver. Our innovative compression and drive technology enables isothermal compression of any gas using high-reliability components that provide high rates of transfer, maintain ultra high gas purity, provide accurate measurement of the transfer rate, and simplify integration with spacecraft systems. In Phase I, we will prove the feasibility of our compressor through performance analysis, proof-of-concept testing, fabrication demonstrations, and mechanical design.

Motiv Space Systems, Inc*

Proposal Title: Clean Orbital Robotic Arm – COBRA

Principal Investigator: Richard Fleischner

Estimated Technology Readiness Level (TRL Begin – TRL End): 2 – 3

Summary Details: The next generation of space-based observatories will benefit from robotic servicing however their performance requires cleanliness not available in state-of-the-art robotics. In addition to telescopes, other applications for ISAM requiring high levels of cleanliness include Silicon-germanium (SiGe) crystal manufacturing and space based biotechnology. COBRA is a unique architecture which provides a completely sterilizable robot arm which, by design, creates no debris. The hyper redundant kinematic nature of COBRA is modular in two degree of freedom (2-DOF) segments resulting in an “n-DOF” arm as it can be configured to any length desired.

Motiv’s 6-DOF customizable force torque sensors can be placed at both the distal and proximal ends of the arm in addition to torque sensing at each joint. That level of sensing can result in high fidelity compliance control. Typically, hyper redundant manipulators are disadvantageous in an Earth gravity environment due to their increased mass relative to conventional configurations and a resulting inability to support their own mass. However, this is not a concern in a microgravity environment. COBRA is a hyper redundant arm completely sealed in an impermeable barrier. Various methods exist to determine levels of cleanliness of a robotic arm and ensure that an arm is sufficiently clean for ultra-clean environments involves a combination of particle detection, surface analysis, and chemical residue testing. The proposed configuration of COBRA presents a straightforward approach to the inspection methods described above as it is a hermetically sealed device withall exterior surfaces exposed for inspection and aggressive cleaning methods. The scalable and modular COBRA system will deliver the clean robotics NASA requires in a short time while also seeding a commercial market for future ISAM activities.

Moonprint Solutions

Proposal Title: Clean Robotics Containment Covers

Principal Investigator: Dave Cadogan

Estimated Technology Readiness Level (TRL Begin – TRL End): 2 – 3

Summary Details: In-space servicing, assembly, and manufacturing (ISAM) is an emerging national initiative to transform the way spacecraft are designed, built, and operated in space.

The goal of the initiative is to develop a strategic framework to enable robotic servicing, repair, assembly, manufacturing, and inspection of space assets.

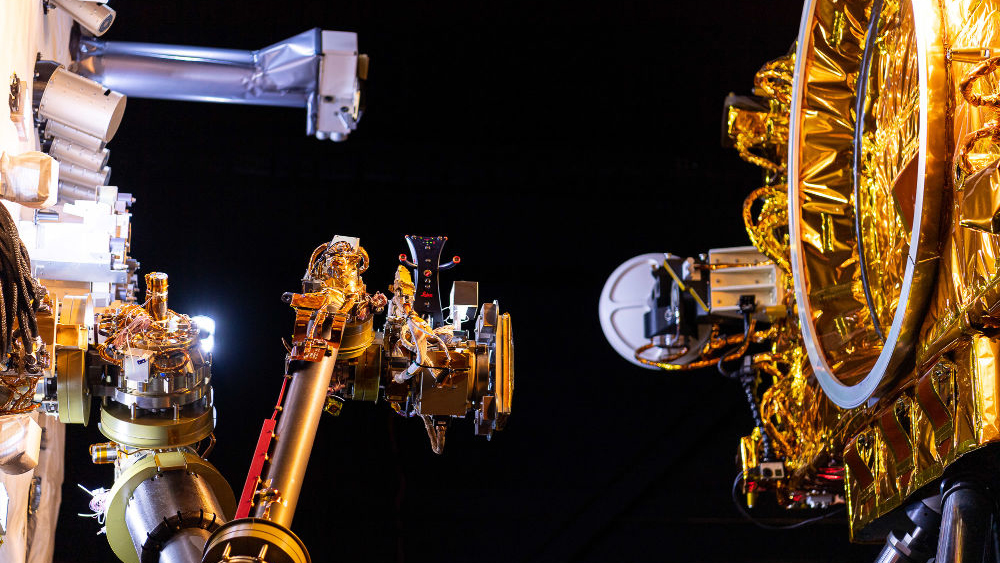

Significant improvements in cleanliness of robotic systems that will enable in-space servicing and assembly of highly sensitive spacecraft and platforms, such as the Habitable Worlds Observatory and other future telescopes (Figure 1). With increasing inclusion of in-space servicing, assembly, and manufacturing in future architectures, there is a need to reduce contamination for operations around highly sensitive platforms. The current state of the art for robot systems poses risks for servicing of platforms with ultraviolet systems that may be susceptible to contamination which could dramatically reduce instrument performance. Moving parts, lubrication, thermal management systems, harnesses, and sensors are likely to result in outgassing, particulate ejection, and other forms of contamination.

Moonprint will develop containment solutions that can be applied to a range of robotic systems to capture and sequester any contaminants from robotic systems.

Containment solutions offer a predictable accounting of contamination sources that can be factored into future standards for quantifying contamination ranges to be expected. This will aid with verification and validation approaches for mission assurance and account for changes in ISAM robotic equipment over time such ascomponent wear or unpredictable circumstances. Containment solutions will support a layered strategy of contamination mitigation to meet mission specific contamination budgets, including ISAM robotic systems and terrestrial clean room equipment such as lifts during manufacture. ISAM cover solutions provide design freedom for robotic system developers and reduce mission costs.

Flight Works, Inc

Proposal Title: Helium Refueling Demonstration for On-Orbit Servicing

Principal Investigator: Jose Torres

Estimated Technology Readiness Level (TRL Begin – TRL End): 3 – 4

Summary Details: Flight Works Inc. proposes to develop an efficient helium compressor for on-orbit servicing applications and to demonstrate key elements of the concept under Phase I with hardware tests. As noted in the topic description, the current state of the art for efficient and timely on-orbit transfer of gaseous fluids, specifically helium, in large quantities is nonexistent. Flight Works has been developing such capability for Xenon up to 3000 psi and will adapt that concept to the higher pressures needed for efficient helium transfer. The approach uses a multi-stage compression scheme withinter-stage cooling to optimize the work done on the fluid and reduce waste heat.

This scheme allows for a large pressure-ratio of both high outlet pressures (6000psia) and low inlet pressure (500 psia) to maximize the applicability of this servicing technology. The Phase I R&D technical objectives focus on obtaining high pressure test data with helium to guide the design of the high-pressure helium compressor. This is done by leveraging the Xenon compressor design and using that compressor as a point of departure for helium. This leads to a preliminary design of the flight unit capable of compressing helium from 500 psia to 6,000 psia with less than 600 W. It also includes the development of a (near) detailed design of a flight engineering development unit to be finalized, built and tested under Phase II.

Congratulations to all the winners! The full list of SBIR Phase I recipients can be found at https://www.nasa.gov/sbir_sttr/phase-i/

About SBIR: The Small Business Innovation Research (SBIR), also known as “America’s Seed Fund” is a partnership between the Small Business Administration and various agencies of the federal government. Per the SBA: “Powered by a network of federal agencies, entrepreneur support organizations, and the Small Business Administration (SBA), America’s Seed Fund advances federal missions and fosters a culture of innovation in the United States.”

*Denotes that the organization is a member of COSMIC. You can review the full membership roster and find out how to join at https://cosmicspace.org/membership/cosmic-member-organizations/